Kameido in Koto-Ku, under the formidable shadow of Tokyo Skytree. If you get off at Kameido station, you will find bustling shopping streets and a full lineup of bars and eateries.

Walk approximately 20 minutes from the station and you will reach an area of re-development. Shopping malls and new house constructions are appearing one after the other.

As part of this, sports facilities and parks, abounding with nature and lawn spaces, provide areas of relaxation for surrounding citizens.

If you find your way through these paths, you will encounter residential areas with a nostalgic feel. You can hear the sound of steel cutting in the factories of the town, as well as the lively voices of kindergarten children.

In one such corner, you can find the “Terazawa Brush Seisakusho”.

Diverse range of hand-planted brushes created by a husband and wife team

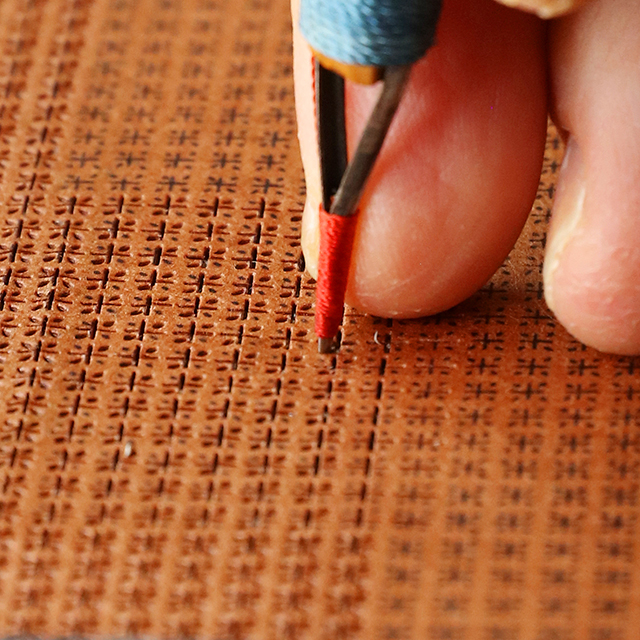

Kazuhisa Terazawa planting a brush at the workshop.

Below the Shinto altar in the workplace, the husband, Kazuhisa Terazawa, plants hairs in rectangular blocks of wood, wearing sandals and a “Dabo” shirt (loose fitting shirt worn at festivals). At the back, his wife is planting hairs in a large, round disc.

His wife planting a disc-shaped industrial brush.

When we think of “hand-planted brushes”, in which the hairs are planted by hand, luxury hair brushes, body brushes, clothes brushes, and shoe brushes may come to mind. However, the uses of hand-planted brushes are not limited to the above.

In fact, they are also highly valued for industrial use.

What Kazuhisa-san and his wife were making on this day were brushes for industrial use.

Current hand-planting technology learned by watching his parents

Terazawa husband and wife team silently planting brushes in their cozy workshop.

The Terazawa Brush Seisakusho was founded around the time of the Tokyo Olympics, in 1964. The starting point for this was his father, who passed away six years earlier, founding a company in Tsukiji, Chuo-Ku, after training at Kyoritsu Brush in Tsukishima.

Following that, they moved to Kameido, where Kazuhisa was raised.

Kazuhisa-san and his wife embarked on this path some 26 years ago. The trigger for this was getting married and having children.

“When I first joined, I fought with my father all of the time. From a young age, I watched my father work, but was not taught much about the work at all”, Kazuhisa-san explains.

80% of orders are for industrial use. As there are company secrets, they are not told about their use.

Metal parts before planting hairs.

If you move your eyes to the work bench, you will see a pile of round metal. It seems that hairs will be planted in this.

What is this…?

If we ask Kazuhisa-san, “We know it is for industrial use, but we have no idea what they are using it for. We make new ones, send them, and re-plant ones that come back. They always come back greasy, but… we don’t know what they are using it for. We use normal screws and nails to secure the hairs, but for this one, we were told not to use metal. It seems that doing so might cause an explosion. I wonder why. Here, we are using shamisen (silk thread)”, explains Kazuhisa.

Deck brush. It seems that after this a 4m handle will be attached.

“This is a deck brush, but the handle section is 4 meters long. I wonder why”, he says. If you look carefully, the hair section is in waves. I have no idea what the 4 meters of the handle would be used for. At the design stage, they give you information up to a certain stage, but after that, it is a company secret.

Various brushes created at the Terazawa Brush Seisakusho.

Brush hairs. There are a wide variety used from animal hair to metal hair.

Additionally, there are large brushes the size of a manhole and giant brushes more than 2m in size. The brush material includes stainless steel, iron, phosphor bronze, horsehair, raccoon hair, goat hair, and weasel hair.

However, in the case of most of the industrial brushes made in the Terazawa Brush Seisakusho, they do not know how they will be used.

Of these, Kazuhisa-san brings a 50cm metal brush and says “What do you think this is? I think most people have never seen this before.”

Brushes with metal hairs planted. What will you use this for?

We really had no idea.

“This is a brush used at a crematorium. It is used for collecting the bones, and so is made of stainless steel. When just heated, it will be hot, so if it was made of hair it would burn. We get orders for these about once every two years”, says Kazuhisa-san in a funny way. We laughed at the fact that they were making these as well.

Using a suede hand-planting brush helps the hand-planting work process

Suede hand-planted brush.

Hand-planted brushes are planted manually by the hands of the craftsman in a careful way, and depending on how it is handled, the brush can be used for life.

From among the brushes used in everyday life, we were shown the process for making the suede brush, at which the Terazawa Brush Seisakusho excel.

Firstly, marks are made on a wooden block, the size of which you could fit in your hand, and holes are made. At that point, phosphor bronze hairs are implanted, and these are connected together by pulling a wire. The quantity of hair is judged according to the feel of your hand.

photo by sakurado(Takahiro Suwa)