Seki City is a small town in Gifu Prefecture, the center of Japan. Seki city or otherwise known as the “Cutlery town of Japan”has a long history of making Japanese swords since the year 1300’s. Before Japan became a unified country,wars were common among emperors and landlords all over Japan and Japanese swords were made as weapons of war during those times.

Mr. Yoshida: Some people considers Japanese swords as dangerous and deadly with its sharp blade. But throughout the years, the history of Japanese swords has changed a lot. Many sword masterpieces has been designated as National Treasures and is considered valuable cultural properties. A few of them are also revered to and is used as charms. I was once commissioned to make a family insignia and with these being said, we may now say that swords are not just weapons of war but now are also becoming treasures of Japan.

Mr. Yoshida is a 3rd generation Japanese swordsmith. He inherited the property from his father who also inherited it from his father. Following the pattern,Masaya,Mr.Yoshida’s son is also destined to be the successor of the family property.

Let’s take a glimpse of the colorful history of the Japanese sword and learn why people are fascinated by the Japanese Katana.

The Jewel Steel called“Tama Hagane” through the Tatara Iron Making method

Tamahagane made through the Tatara iron-making method is the main material in making Japanese Swords.

The Japanese sword is only made out of a particular Jewel Steel called“ Tama Hagane”. A steel exclusively produced in Okuizumo, Shimane Prefecture.

There are two major reasons why this place is so particular:

Firstly, The Izumo Grand Shrine (Izumo- Taisha) is among Japan’s ancient and important shrine located at Shimane Prefecture. Izumo has a lot of legends derived from Japanese mythical stories because it is believed that Shinto gods gather and meet once a year at this particular place to decide on the people’s fate.

Japan’s most famous mythical story related to Japanese sword

: Yamata no Orochi

Orochi is a legendary Japanese Dragon which is said to have 8 heads and 8 tails. Susanoo, the Shinto god of the sea and storms is believed to have defeated the dragon and got the mystical sword called“ Kusanagi-no-Tsurugi” from one of its tails. The sword is now one of the Three Sacred

Treasures of Japan and is currently preserved at the Atsuta Shrine, Aichi Prefecture.

Secondly,

Ancient Izumo village was believed to be a very strong village.They have developed their original iron making skills derived from the Korean peninsula. Izumo area has all the materials for making iron steel such as iron sand, enough wood to make charcoals among others.

This is an important Japanese tradition technique and methodology that should be passed on to Japan’s next generation.

The movie“ Princess Mononoke”produced by Studio Ghibli, talks about a small village that makes iron for a living. In the movie, you can see a lot of women send air to the big furnace with bellows called “Tatara”.

Making the highest quality iron does not particularly need high technology process.

Let’s take a look at these basic steps:

・13 tons of charcoal and 13 tons of iron sand is oxidized for 3 days in low temperature

・After oxidation, Only 3 tons of mass steel called “Kera” is produced from the 26 tons of materials stated above.

・Only 1 ton of a lump steel called “ tama hagane” is taken out from the kera through.

Tama Hagane has a good balance of carbon that makes it the perfect material for making Japanese sword.

Mr. Yoshida :The sword making tradition has changed a lot through out the years since 700 years ago. Japanese swords made during the Kamakura period (1185- 1333) has always been the best model for Japanese swordsmiths. But the method and matelials has been slowly being replaced.That is why it is difficult to make swords with the same quality as those of the Kamakura period. Therefore, Shimane prefecture is just the only place we can buy Tama Hagane

Unbreakable, Unbending and Razor sharp ~the process of making Japanese sword~

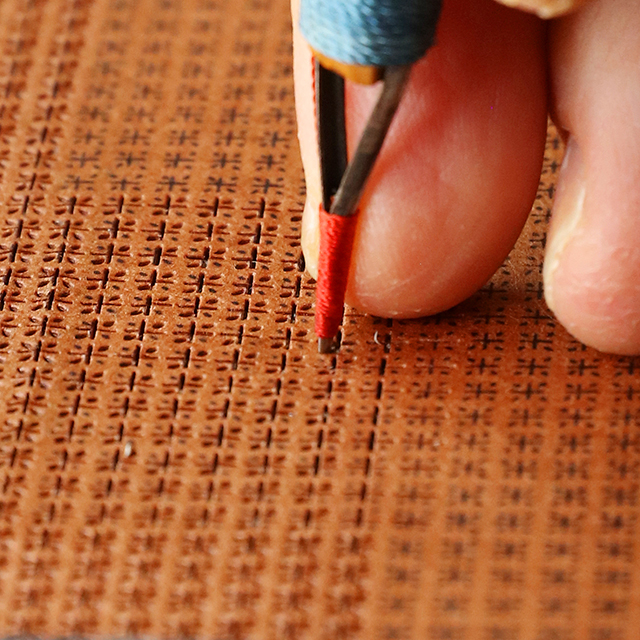

Gunome called the Three Cedar Tree is a traditional temper pattern in Mino-den.

There are 4 basic processes in making Japanese sword: Welding, Forging. Shaping and Quenching

“Welding”

A block of Tama hagane contains a lot of impurities. It needs to be hammered repeatedly and heated until it becomes 3-6 mm. The swordsmith now breaks and separates them into hard and soft steel parts. An experienced swordsmith can tell the difference by just looking at the edges of the steel. He then welds the same pieces together on a spatula-like material.

While controling a sufficient heat temperature, flattened layers of Tamahagane must be welded into the steel block.

After welding into the steel block, the process of forging and folding is repeated.

“Forging”

Forging is the process of removing impurities by creating a billet and repeated hammering of the formed steel. This is one of the most important process as it cleanses the steel to make high quality steel. A forging demonstration is held every first Sunday of the month in Seki City.

Sounds of striking billet with a heavy hammer and sparks from the heated steel are very exciting to witness. While the audience are astonished by the craftsmanship, it is noted that the swordsmiths do not talk nor speak at all throughout the process.

“Aizuchi wo Utsu”, A famous Japanese proverb, which literally mean to strike a hammer, is derived from this process. But a deeper meaning is also understood from this, which is to understand each other through nodding. With this, we may now figure out why the swordsmiths understand each other without speaking.

“Forming”

Forming is the process of making the sword tough or unbending. The secret of this process is to place the soft steel in the center and the hard steel on the outer side, then heating the billet to draw into the bar. The bar now has a rough shape of a sword.

“Quenching”

Quenching is the process of making the sword unbreakable. The full length of the blade is heated in an evenly blazing temperature then immediately immersed in water.

These processes are still applied even up to this modern times.

Mr. Yoshida : A lot of people misunderstand forging as the training to make the steel hard, but actually it’s how we make the steel flexible and smooth through mixed elements. For me, all these processes makes me more passionate and makes my body and soul stronger.

This is the training skill people call forging = tanren.

Challenging to the national treasure class

According to Mr. Yoshida the appearance , steel surface,temper pattern and the tang are most important points.

There are 5 major design classification of Japanese swords called the “Gokaden”

・Soshu-den ( Kanagawa prefecture )

・Bizen-den ( Okayama prefecture )

・Yamashiro-den ( Kyoto )

・Yamato-den ( Nara prefecture )

・Mino-den ( Gifu prefecture )

The Mino- Den, which Mr. Yoshida belongs to, was only established 700 years ago. With this, the Mino- den is said to be the youngest among the 5 traditions,but the only one with a 700-year continuous tradition. Other traditions may have been established earlier yet along the way has stopped and then restarted again or has lost its successors. The development of the Japanese sword has its peak during the Kamakura period (1185-1333) and the swords made during this time is the best role model for modernly made swords.

Japanese swords must have the signature of the swordsmith,while others don’t have one.For modern swords, the swordsmith signature is required.

Mr. Yoshida : I still have a lot to learn in sword making. I usually make 10 Japanese swords within 6-months period however, I still have not made my own masterpiece. From the 10 swords I make, I register only about 3 of them then break the one’s I don’t like. It’s always been my dream to be able to make a sword like the ones from the Kamakura period and being able to make my own masterpiece will always be my goal as long as I exist.

Mr. Yoshida has a strong commitment to introducing the Japanese Sword market not just to the Japanese people but to foreigners as well. Mr. Yoshida holds

Forging demonstrations and also has unique small knife making programs in his studio.

If you are interested in taking part of these you can contact him